To wash or not to wash? That is the question. If you've been sewing for a while, you've probably come across this topic. And you certainly know that this question divides the sewing community into two camps, and some members of both camps are almost willing to lay down their lives for "their truth".

I would like to start by saying that the procedures described below are just recommendations. You probably have your own preferences, little tricks, and favorite ways of doing things. The following lines contain my findings from several years of daily work with various fabrics. However, your experience may be different and that's fine. :)

Surely, like me, you are very excited when you get new fabric. You'd like to start sewing right away, wouldn't you? Unfortunately, this is not always possible. Before sewing and even cutting, you should wash certain fabrics, dry them, and iron them properly. Why? There are two main reasons:

- The fabric should be CLEAN and pre-shrinked.

- The fabric should be crease-free before cutting.

You may think that the new fabrics are clean, but unfortunately, this is not the case. Mass production of textiles and cheap and low-quality clothing harms our environment.

"Harmful waste from chemicals used in the production process pollutes rivers and seas, not only destroying the lives of (mostly poorly paid) employees but also our planet. The fashion industry is one of the biggest polluters. The negative impact on the environment is present throughout the entire life cycle of fabrics, it starts with the sourcing of materials, and sometimes it does not end even with the disposal/recycling. Currently, the most used materials are cotton and polyester. Cotton is natural, so it can't be that bad, can it? Well... Various pesticides and herbicides are used during the cotton cultivation process, the plant needs a lot of water and most of the production comes from giant plantations in China, the USA, India, and Pakistan - unfortunately, unsuitable working conditions and child labor are not uncommon in some of these countries.

See also: Learn to use a sewing machine (straight & curved seams)

The production of polyester and other synthetic materials is a burden on the environment for several reasons. These materials are made from oil and other non-renewable resources, which is associated with another problem - complex and long decomposition process. The use of polyester is one of the main reasons why the clothing industry is among the most polluting industries in the world. Various bleaches, dyes, stabilizers, and other chemicals are used in production. These substances threaten not only our planet but also the health of individual people. This chemical cocktail pollutes the air, water, and soil. ” (Source: Atelier.cz)

“Antifungal substances, chemical dyes, stabilizers, and flame retardants - this poisonous cocktail is found not only in the ready-made clothes but also in the fabrics we buy. Artificial textile additives are toxic to us and the environment as a whole. You won't find much information on manufacturers' labels to warn consumers about the dangers of exposure to chemicals. Once the cotton is harvested, it goes to a textile factory, where it may or may not be blended with synthetic fibers. During production, cotton is often treated with various chemicals, which make it more attractive to the customer. Fabrics are often treated with chemicals to reduce odor or prevent creases, for example. The goods then look nice in the shop window and more easily attract the attention of shoppers. Thanks to synthetic plasticizers, the goods are softer and do not crease much. However, these man-made chemicals can have unpredictable adverse effects on our health… Formaldehyde, for example, is often used in the textile industry to prevent shrinking and stabilize colors. ” (Source The Epoch Times)

Mass production of textiles and cheap and low-quality clothing harms our environment.

"Formaldehyde is highly toxic to most organisms. It is a mutagenic and carcinogenic substance (1st category according to IARC). Humans can be exposed to formaldehyde by inhalation, ingestion, and skin contact.… It may cause atopic eczema and various allergic reactions. ” (Source Atrnika)

If you are more interested in ecology and health, I recommend you follow Facebook Fashion Revolution. You can also take a look at Kamila Bouda's blog – Moymi.com.

But let’s step away from the ecological and health aspects… Have you ever applied fusible interfacing to a brand new fabric just to find that it came off after the first washing cycle? Did your painting ever disappear from the fabric, even though you “baked” it with the iron before washing? It's because you applied the materials to the wax layer that the fabrics are usually covered with, and it simply washed away.

Another important reason to wash the fabric is its tendency to shrink. Each manufacturer states the % of shrinkage, and you should take this into account when purchasing the fabric. Wash the fabric as you intend to wash the finished product in the future. So if you bought a beautiful knit for a T-shirt, wash it according to the manufacturer's recommendations (usually up to 40°C) and then wash the finished T-shirt in the same way. If you plan to dry the T-shirt in the dryer, dry the fabric too. Thanks to this procedure, the finished T-shirt will no longer shrink.Washing/drying may be different for different fabrics, but the idea is always the same - treat the fabric the way you will treat the finished product.

I will not put a bouclé for “Chanel suit” to a washing machine and I will not run it through a dryer. I would never do that with the finished garment, so I won't do it with the fabric…

Antifungal substances, chemical dyes, stabilizers, and flame retardants - this poisonous cocktail is found not only in the ready-made clothes but also in the fabrics we buy…

The cutting edges of woven fabrics must be treated before washing. I usually clean them on my overlock machine. If you do not clean the edges, washing could damage the fabric.

I don’t clean the cutting edges of knits before the fist washing cycle, but it is necessary to take into account that they will get twisted and wavy (this is especially true for thin single knits). You will need to straighten the edges before sewing, you can read more about it here: How to sew a T-shirt in a few minutes.

Fusible interfacing doesn’t adhere well to creased fabric, folds can cause various inaccuracies, and the creased fabric is simply harder to work with overall.

But all this "extra" work is one of the biggest advantages of home sewing. I can't imagine that a clothing brand would wash the fabric properly during the production process, that they would unwind meters and kilometers of fabric from the rolls just to stuff it into washing machines... Surely it has ever happened to you that the clothes you bought got deformed and bleached after the first wash.

The composition of a particular fabric is also important for deciding whether to wash it before sewing. If we leave out the fact that someone (like me :) ) does not want to work with fabrics full of various chemicals, and we will focus only on the properties of the material (colorfastness,% of shrinkage, etc.), we will notice one more important thing. Synthetic materials (polyesters, acetates, polyamides...) are stable. In other words, fabrics that are made of synthetic fibers do not shrink and are usually colorfast (they do not bleed color). Fabrics like synthetic lining fabric, polyester laid-in knits, fleece, softshell, and others won’t shrink. Some may bleed colors, but that doesn’t happen very often. So if you like artificial materials and you don't mind working with an impregnated and otherwise chemically treated fabric, then you don't have to wash it. The question is whether you want to wear artificial materials, but that's a topic for another article.

I almost always wash my fabrics and you should also consider doing it. But as I said - it's just a recommendation. I wash some fabrics in the washing machine, others by hand. It depends on the material and how I want to treat the finished product from the given fabric. I will wash children's sweatpants in a washing machine (40°C) s and I will also dry them in a dryer. Kids often get their clothes dirty, so I expect that in advance. And so I would treat the new fabric for sweatpants just as I plan to treat finished sweatpants - I would simply wash this new fabric in a washing machine with a small amount of washing powder (without fabric softener) and dry it in my dryer. Then I can be 100% sure that my sweatpants will not shrink or deform in any way. After the first washing and drying cycle, I also have a better idea of how the fabric behaves. Does it tend to lint? Do colors fade? You may also put the fabric aside after the first wash because you will find that it is simply not suitable for your particular sewing project. This isn’t a pleasant surprise, but it is better to find out before sewing.

I almost always wash my fabrics and you should also consider doing it. But as I said - it's just a recommendation. I wash some fabrics in the washing machine, others by hand. It depends on the material and how I want to treat the finished product…

Let's now look at “classic fabrics” - I mean fabrics designed for sewing formal clothes, such as various blouse fabrics, coat fabrics, costume fabrics, and so on. I usually wash these by hand.

I fill the sink with warm water (30°C - 40°C - depending on the fabric) with a small amount of washing powder and immerse the fabric in it. I can see straight away whether the fabric bleeds color or not. Then I let the fabric soak for about 20 minutes and rinse it in cold water.

Now we can move from washing to pre-shrinking. There is a difference. We wash fabrics to get chemicals out of them and pre-shrink them at the same time. Pre-shrinking is just about this one thing - pre-shrinking. You can pre-shrink textile fibers in two ways - with high temperature and with heat shock. You can go about it in these three ways:

- Iron the fabric with hot steam - this procedure is suitable for woven fabrics.

- Soak the fabric in warm water and then transfer it to cold water (heat shock).

- Wash the fabric (without fabric softener)

Thread direction vs. printed motif

Update 25.3.2019: I’m adding a message from Majka, who also deals with washing and pre-shrinking. Here are Majka's message and my answer.

Hello, Petra, I read your beautifully written article on washing and pre-shrinking.

My knits sometimes shrink unevenly which then causes pattern matching issues. If I then position the pieces only according to the motif, they are slanted relative to the direction of the warp/weft, which of course causes problems - T-shirts made of slanted pieces tend to twist awkwardly.

For this reason, I stopped washing/pre-shrinking my fabrics. But then I came across several knits that shrunk a lot (finished T-shirts shrank by about 5 cm), so I started washing and pre-shrinking again, but of course, the pattern matching problem did not disappear. Have a nice day, Majka

Hello Majko, this is a well-known problem. But it has nothing to do with washing - the motif was probably slanted even before you bought the fabric. In the printer, knits are unwound from rolls on which they were not wound completely evenly. Due to the natural elasticity of knits, this problem is practically impossible to solve. The weft lines are always at least a little curved - for example so that the middle part of the fabric enters the printer a little before the parts near the selvages do. If you get into this situation, you can just choose between a twisted T-shirt with a matched pattern or an undeformed T-shirt that has a badly matched pattern. Neither is a win. Finding a nice and well-printed motif on a knit is almost impossible. Buying a well-printed knit in a brick & mortar store is difficult and you can forget about it when shopping online... That's why I just don't buy knits with motifs that require exact pattern matching. I choose motives that allow me to follow only the direction of the weft/warp during the pattern layout phase. My advice is to avoid buying cheap fabrics with motifs that require a perfect fit, or to buy so-called jacquard knits - their patterns are “woven”, so they cannot be slanted in relation to the weft/warp.

Have a nice day, Peťa

My tip: I recommend shaking the knits before sewing and letting them rest. You can let the knit lie freely on the ground or the table for 24 hours, the unevenness caused by poor winding should disappear.

To sum up, wash the fabric before sewing (or at least pre-shrink it - it depends on the material, sewing technique, and your preferences) and iron it. If you decide to wash the fabrics before sewing, do so in the same way as you plan to wash the finished products.

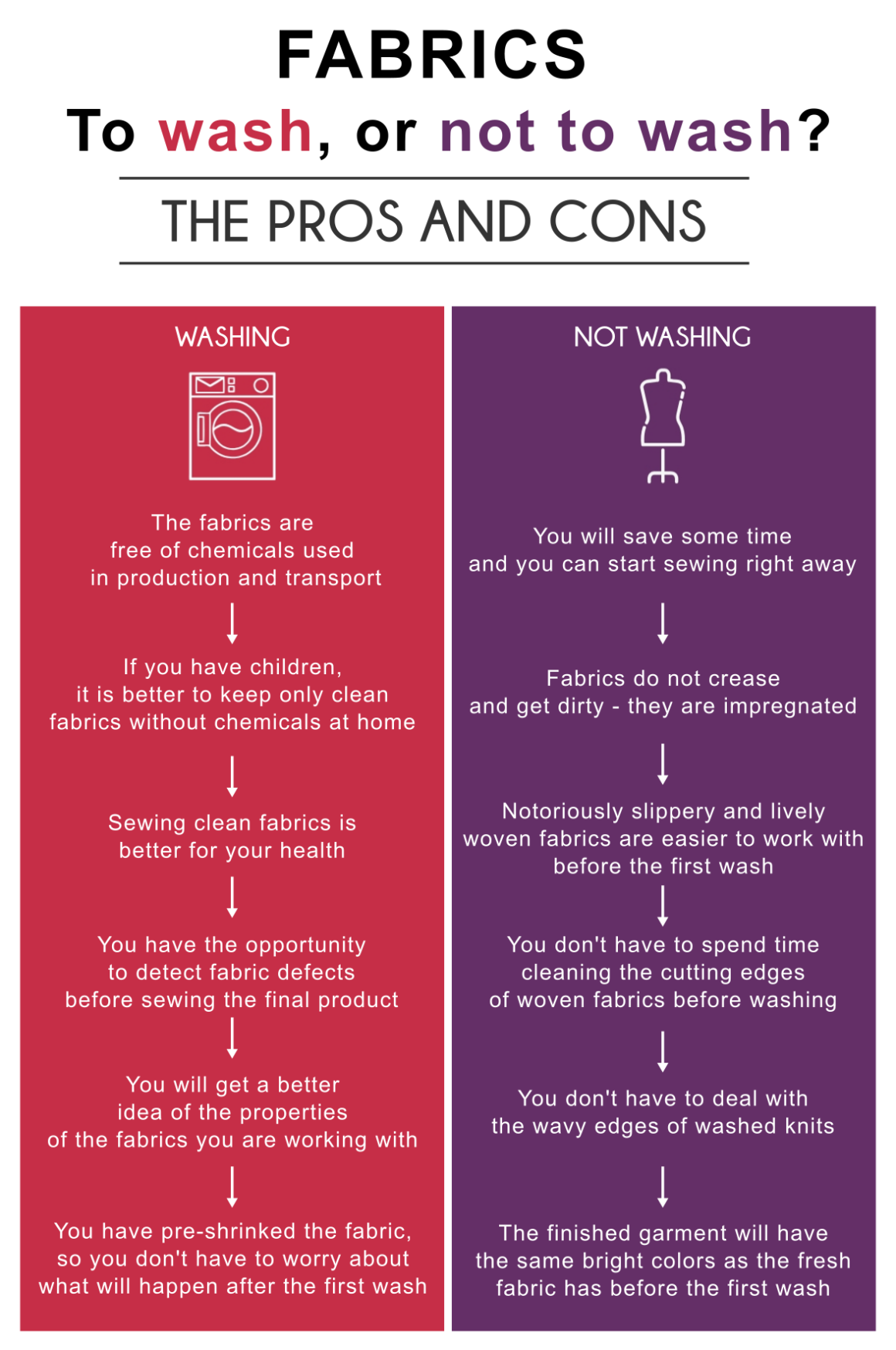

The main points of this article can be found in the infographic below. It contains the pros and cons that are associated with (not) washing fabrics.

You can find other useful sewing tips here: Tips & Tricks.

And how do you do it? Do you wash your fabrics or not? I will be looking forward to your opinions in the comments below…

Have a nice day, Petra